Custom Large-Scale Hole Punching Machine for European Port Construction

The Challenge

We received an inquiry from a contractor in Europe who needed to punch holes in 14mm thick H shape channel steel at a busy port construction site. The steel sections were unusually wide, presenting a significant challenge: the machine had to be capable of punching both in the web (the vertical center part) and precisely in the middle of the flanges (the horizontal legs). Our standard, off-the-shelf machines were simply not capable of handling this specific and demanding workload.

The Solution

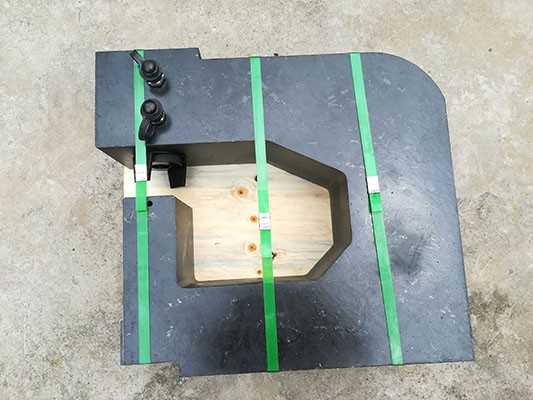

It was clear that a customized solution was required to meet the client's unique on-site demands. After continuous communication, the client carefully evaluated all their hole punching scenarios and sent us a detailed list of the required working capabilities. Based on these specifications, our technical team designed and engineered a large-scale hole punching machine specifically for this project.

The Result

The result was a resounding success. The client was extremely satisfied with the machine's outstanding working capacity and performance at the job site. We were equally delighted—not just because of the successful business deal, but because we were able to deliver a personalized, tailor-made solution that solved a complex problem for our customer.